In discussions about things to do in the Helena area, we were told by several folks that the boat tour of "Gates of the Mountains" was a must-see. So, next morning we bid farewell to Ben and Krista and headed north to do the tour. We got a bit more than we bargained for. The photos below are what we saw.

As we prepared to leave, I got this shot of Ben and Krista's ranch estate.

The super-shop. Note the mog inside the door. After we left Ben's place, we headed north for the boat tour called Gates of the Mountains.

In the marina on the Missouri River, I spotted this group preparing to go out on the river/lake. I thought that it was interesting that Fido knew his place.

The tour headed out of the marina and downstream through a large canyon in the limestone. The tour provided details about the history of the canyon and the hardships endured by the Lewis and Clark expedition when they came through this area in 1805. I should be made of such stout stuff.

We spotted a natural window in the limestone cliffs.

Strong forces were at work when this uplift occurred. Note the folding, warping and upturned bedding of the limestone.

We spotted this group of pelicans heading generally southward, perhaps for the winter.

We spotted another larger window in the canyon walls.

The tour guide pointed out some ancient pictographs high on the canyon walls. We were only able to view these from the boat, thus the somewhat low resolution photo.

The finer details of the pictographs were obscured by the shadows of the overhanging cliff.

The guide described this plant as a rare kind of rose, but it looked more like lichen. According to him, this blooms like a rose!

This small canyon was where a number of smoke jumpers were killed by a forest fire they were fighting. Once we returned to the marina, we headed west on Hwy 12, then north toward Glacier.

About 10 miles north of a small village called Avon, both Kathleen and I noted the truck lurch. The lurch was followed by a vibration, so we stopped to inspect. When I did a temperature check of the hubs with my hand, the driver's rear was smoking hot. Literally. When I got under the truck, I could see the smoke coming from the hub. I took off the wheel for a closer inspection, including checking the oil level in the hub. There was no oil in the hub, but no sign of a leak either. Only when I looked on the inside of the wheel did I see the cooked oil. It never produced the pin-wheel leak pattern that I expected. The conclusion was that the bearing failed first, not the seal. Not all that surprising given that the truck is 30 years old.

We were close to nothing and no cell service at our location, so I filled the hub with what I had which was engine oil. There was no leakage once the hub was filled, but after we reinstalled the tire and let it down off the jack, the oil leaked directly out onto the ground. This implied that the bearing seals, at least, were bad and did not bode well. The sheen on the hub in the photo above is from the oil filling process, not from a leak. We decided that the damage was likely already done given the heat of the hub, so we limped back the way we came at 15 mph until we hit cell service. An hour later, we were back in Avon and were able to call Kai and Rob to get their assessment of the situation. Rob stated that he thought that a low-speed return to Helena would be the most reasonable solution, so we headed east over the 6000+ foot McDonald pass back to Helena.

When we got back into cell range on the east side of the mountain, we called Ben again and he offered up his shop. In the 2+ hours it took us to get back to his place, he re-arranged his shop to allow us to park well away from the door to provide extra room for the repair actions that were to come.

His shop is so big that there was plenty of room for both his boat and my rig. The drive back to Helena was rather stressful, so we decided to hold off the actual repairs until the following morning.

The first action was to loosen the 10 hub bolts. This turned out to be more effort than was expected. These bolts are at 290 ft-lbs torque and were a bitch to get off.

The first, and so far, only casualty was my socket. There was minimum clearance between the hub walls and the bolt heads so a thin socket was needed and was not up to the task. Ben had a hardened socket and I was able to get the rest of the bolts loose after some sweating, cussing and a 6 foot cheater bar.

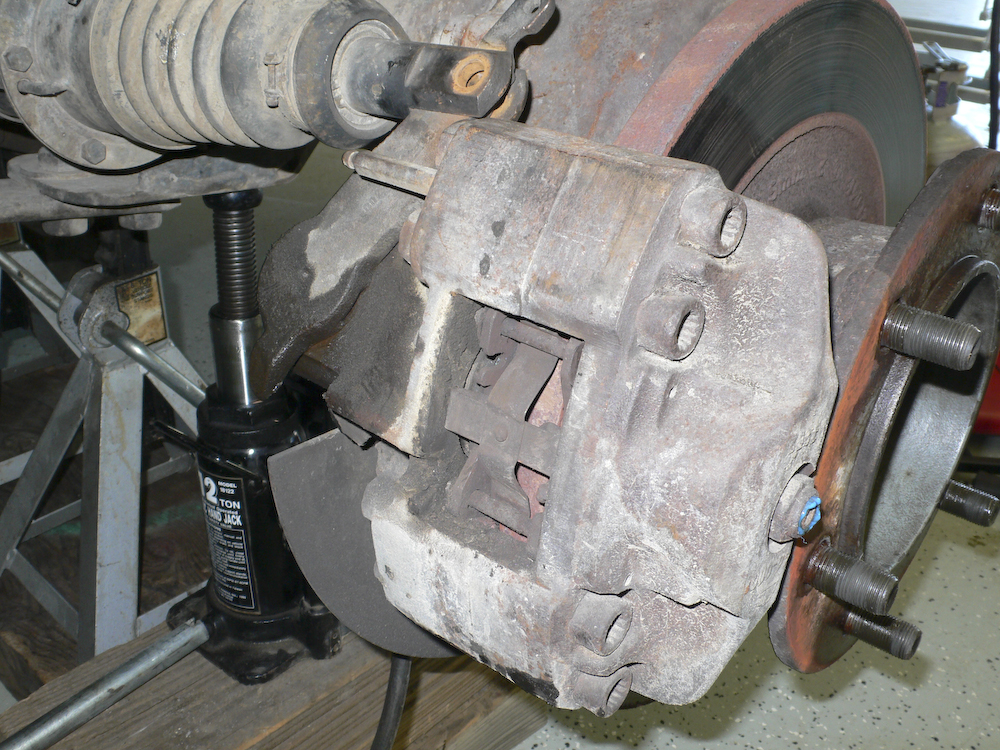

After the hub bolts were loose, the wheel came off and then the parking brake actuator was disconnected. I removed the cover for the disc brake pads, but in the end decided not to remove them.

Next, the wheel mount and brake disc was removed. This assembly is heavy, so I used the engine hoist and some rope to insure I did not get a painful surprise on my foot.

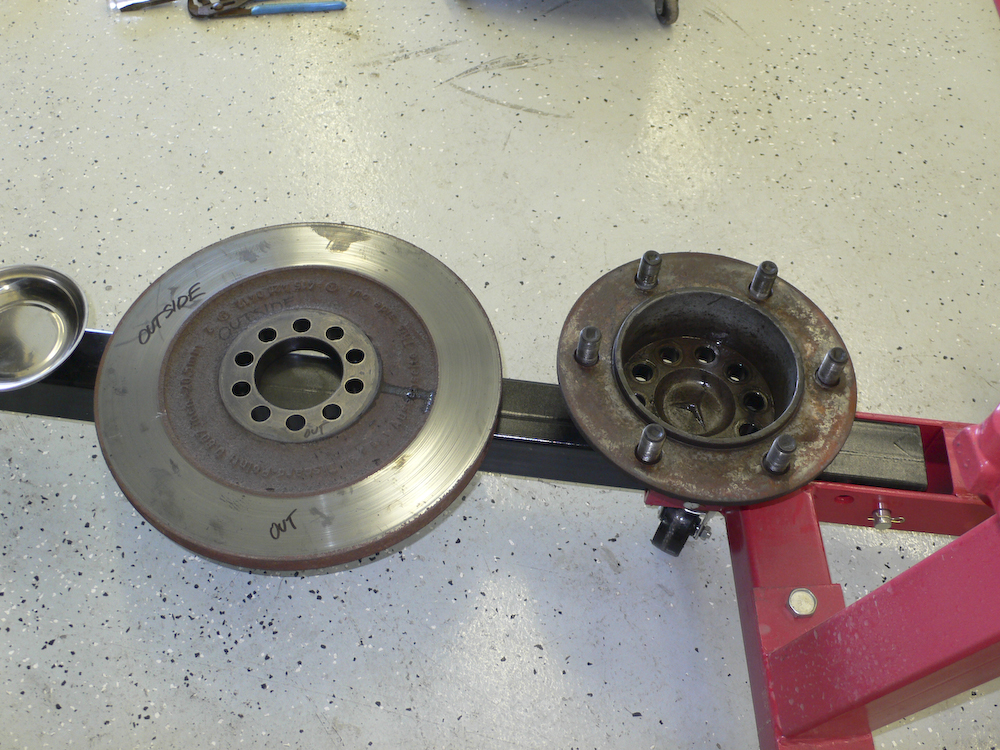

The removed parts were placed aside for inspection.

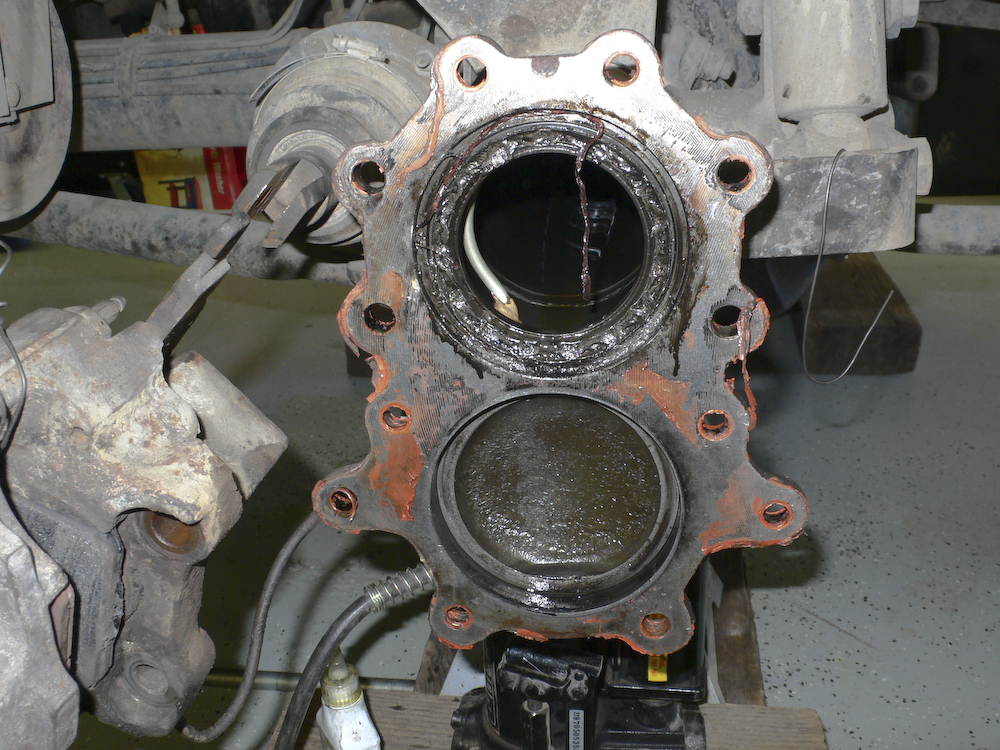

As expected, the seal on the lower bearing has failed.

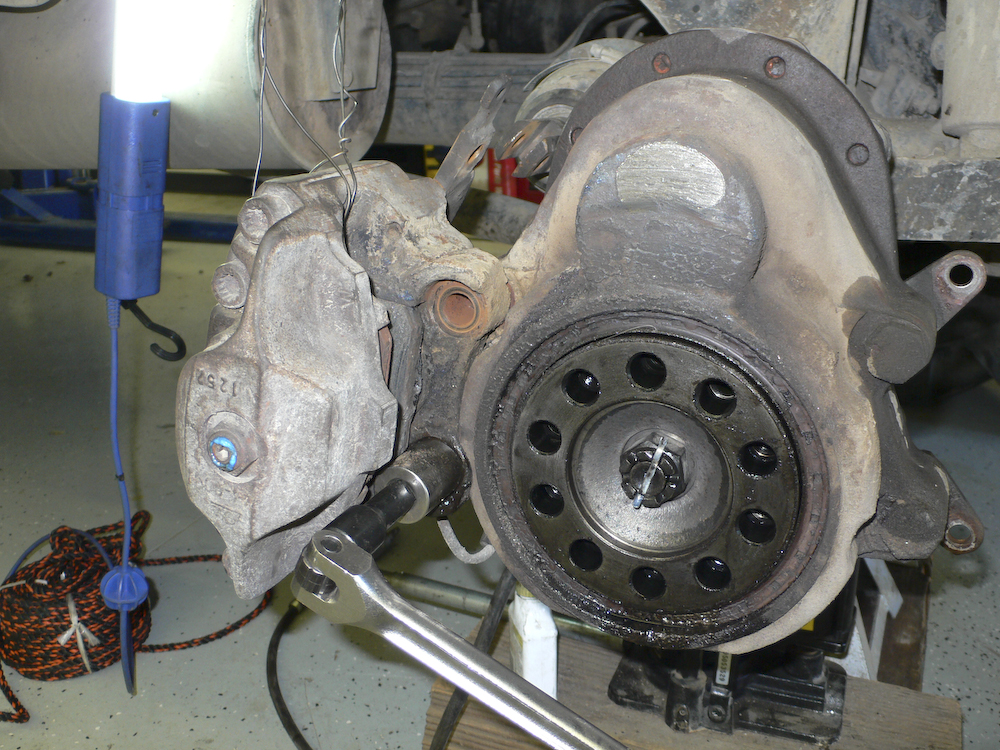

Note the marks on the hub where the disc rotor has scraped against the hub. This is because the bearing has failed and had enough slop to allow the contact when the hub was under load from the weight of the truck.

The hub has scored the rotor, but it is still usable.

The brake caliper assembly was supported by baling wire to prevent kinking of the lines when the assembly is unbolted from the hub. The bottom bolt was a zero clearance bolt and was really, REALLY hard to get out.

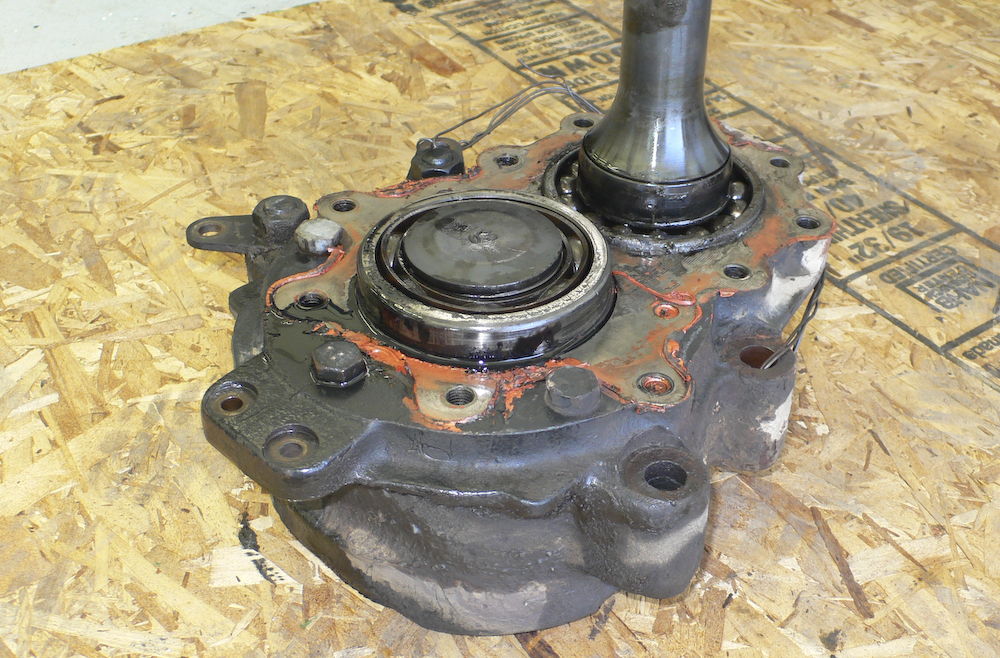

A set of wires were strung to support the hub casting so that when I unbolted it from the axle, it did not go south. I used Ben's engine hoist to take a small strain on it while it was tapped and levered apart. The bearings were still seated in the housing, so it had to be pulled straight out.

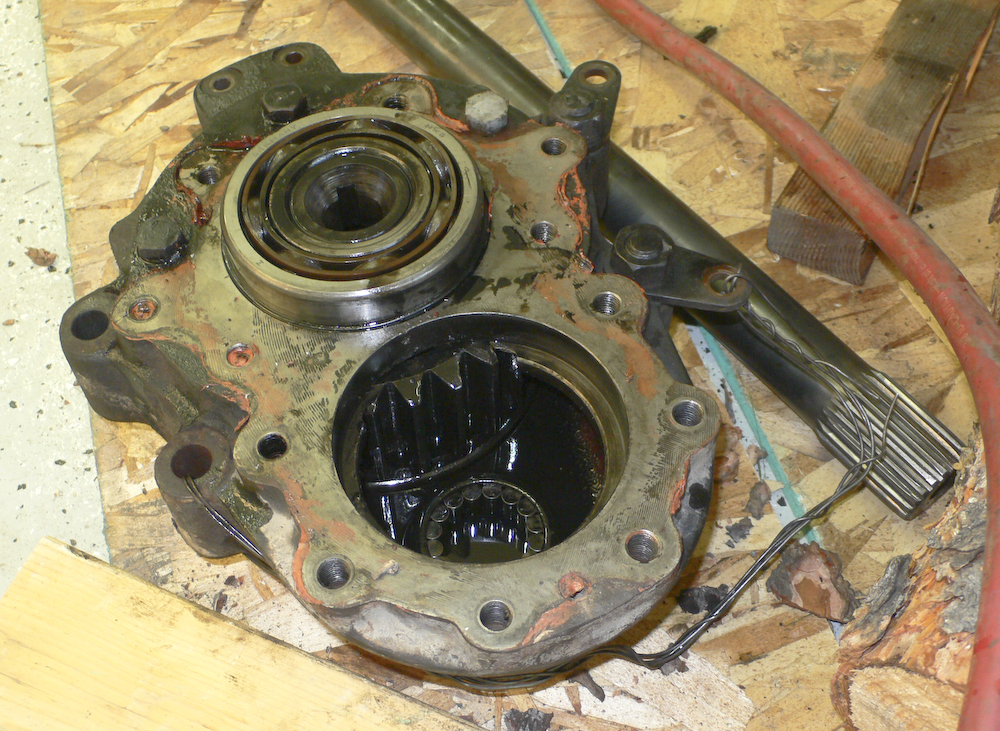

I got it apart, but it was not a pretty sight. The top bearing is fully roasted and metal debris can be seen in the bottom cavity. Dark, burned oil has been vented into the axle tube and has contaminated the differential oil.

The short side of the axle also came out with the outer assembly. Both bearings are damaged, but the top one is worse. Note that there is no plastic seal on the smaller bearing. It was burned into the oil seal of the axle tube as can be seen in the previous photo.

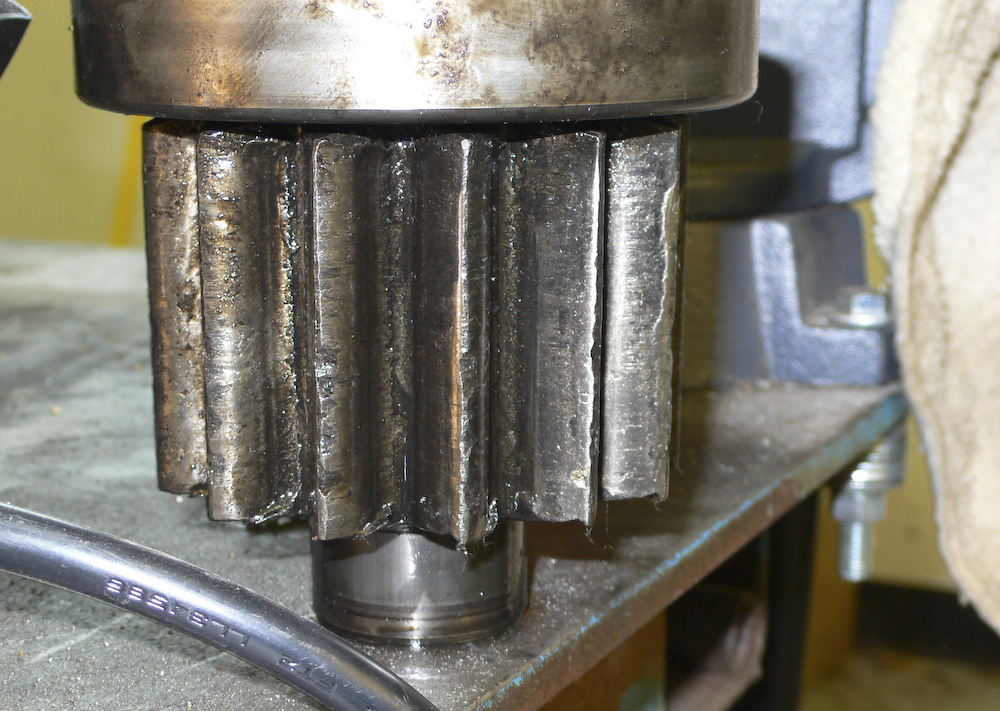

The axle gear is badly damaged from the heat of the bearing failure. This gear, as well as it's mate and all the bearings will have to be replaced.

The damage to the wheel gear is not clearly visible, but you can see the rough edges of the gear. Note the nasty black oil that has been burned. Most of the 30 wt oil that I added was burned off during the limp back to Helena.

The end of the axle does not appear to have been damaged. Note the spiral splines on the end. It seems that there are a number of parts configurations for the 1300L and I was lucky that Rob was able to find parts among his inventory. He had to disassemble 6 axles to find the right combination.

As a consolation prize, the Montana skies were clear and the moon was bright. This shot was taken from Ben's backyard.

Despite one broken socket and a bunch of off-color words issued in frustration by yours-truly, I did manage to get the hub assembly fully apart. Inspection proved what I already knew which was that both gears and all the bearings were toast. Thanks to Rob Pickering's inventory of trucks at his shop, he was able to put together a full assembly and is having it shipped to me. We will exchange the new one with my casting. The internals, of course, are trash. Thanks to Rob, Kai and Ben Palmer for their support. Assuming the parts arrive in a timely manner, we should be back on the road in a few days.

| Previous Adventure | ||

Photos and Text Copyright Bill Caid 2008, all rights reserved.

For your enjoyment only, not for commercial use.