After

much use of our 1300L Unimog/Alaskan camper combination, both Kathleen

and I concluded that a bigger living compartment was in order.

The trick would be to find a platform that offers more room (a bigger

"footprint") and still provides good off-road capability. After

much research, I concluded that the Mercedes-Benz 1017A 10 ton 4x4

cargo hauler was just the ticket. I found one of these trucks "in

country" at Rob Pickering's place in La Junta, CO. Since we were

on the tail end of our east coast mega-trip, we decided to stop by and

physically inspect the rig. After seeing, and driving, the truck,

we concluded that it was the platform that we were seeking. While

on the road, we were also performing a search for an appropriate living

compartment to go atop the truck. The Alaskan camper has a rather

unique feature which is a top that raises and lowers. When

traveling, the top is down to provide a lower center of gravity.

When parked, the top is raised to allow head room. Our Alaskan, a

1978 model, has a manual hydraulic pump that is used to lift the

top. It only takes a few minutes, but it is somewhat of a

nuisance.

Kathleen's research on the web suggested that a Hi-Lo Trailer might be a good cabin. Further research showed that the company had recently gone out of business due to the recession and that there was a new unit of the correct length located in Colorado Springs, CO about 100 miles from the location of the 1017A. After seeing the trailer, we bought it on the spot. The trailer was half of the list price and while there were some issues that needed to be addressed, it was a good value overall.

We

towed the trailer to Rob's shop in La Junta to prepare for modification

and assembly of the combined unit. Due to Rob's schedule, we

ended up returning to San Diego first and then coming back to La Junta

a few weeks later when an open spot in the schedule was available.

The photos below are what we saw.

Kathleen

measures the height of the cab on the 1017 prior to purchase. We

were somewhat concerned about the overall height of the combined rig.

A

side view of the 1017A. This is the "before" photo with small

tires and dual wheels.

The

bed of the 1017 was big, heavy and just not needed. So, it was

unbolted and lifted off the frame with a pair of fork lifts.

The

naked bed shows two huge cast iron "saddles" that were pivoting mounts

for the bed.

These

mounts were massive and it is not clear to me why they were so

big. But, no matter, they were removed to make room for the HiLo.

We

drove the 1017A over a loading dock wall to test the articulation and

determine how much frame flex there would be in an extreme off roading

situation. This information is important in the design of the

sub-frame to support the camper.

We

towed the HiLo from the sales lot in Colorado Springs to La

Junta. The photo above was taken in a parking lot off of I-25

south of CS. The folks at the trailer sales were nice enough to

loan me some equipment (like a hitch extension) to allow me to safely

tow the trailer to La Junta. In the photo above, note that the

trailer is in the lowered, travel position providing low wind

resistance. Also note the gray side skirts that will be removed

and replaced with tool boxes.

When we got the trailer into Rob's shop, we raised it to perform an interior inspection. We slept in the trailer that night because it provided much more room than our Alaskan camper.

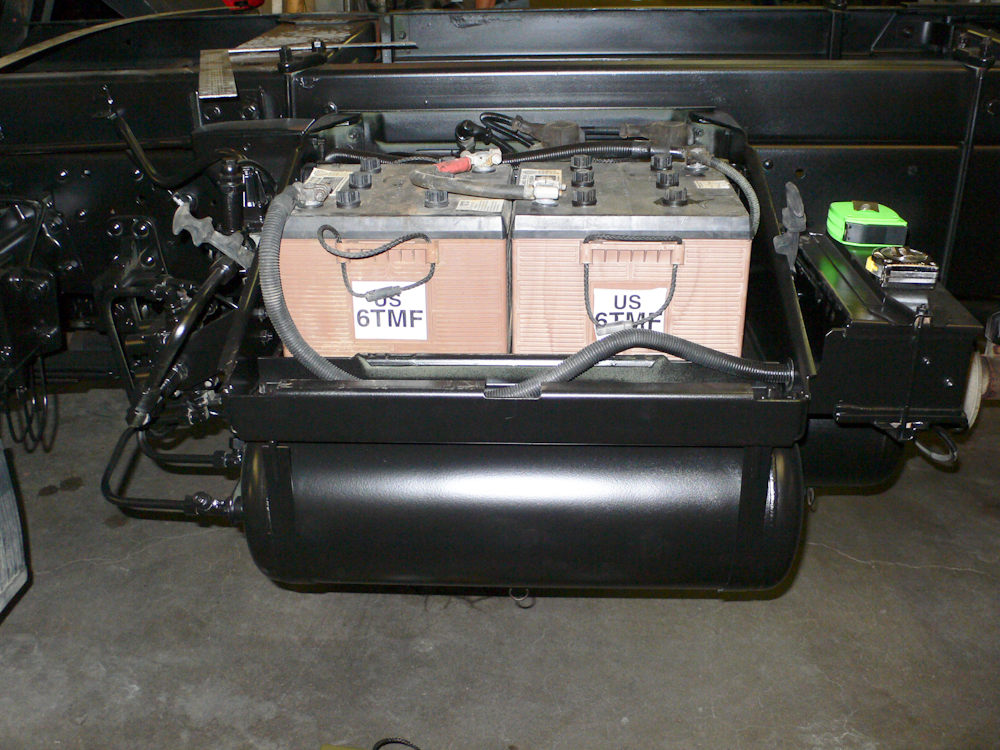

Rob's

schedule, and the birth of his twins, prevented him from working on the

1017 project for several weeks. So, we returned to San Diego to

address house chores that had arisen during our 5 months of

travel. We returned to La Junta and found that Rob had painted

the chassis of the truck and ground off the large cast iron bed mounts

in preparation for the camper fabrication actions. Above is a

photo of the newly painted battery box and air system.

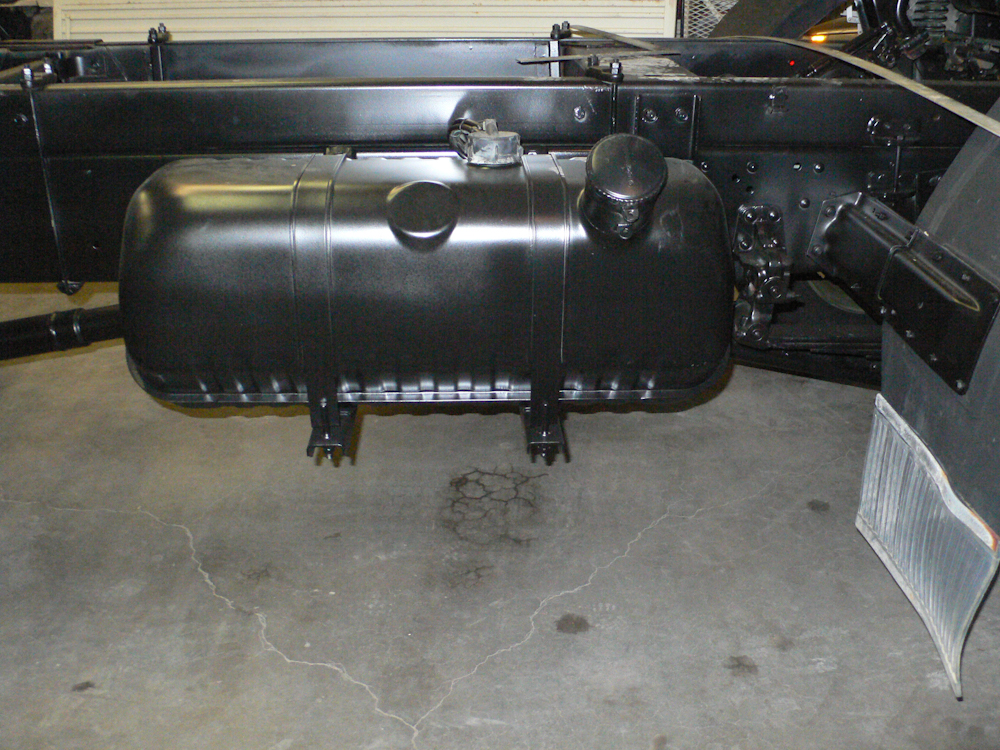

The

air system and cab lift jack.

The

previous bed mounts were removed and the chassis was painted satin

black.

The

exterior of the fuel tank was cleaned and painted as well.

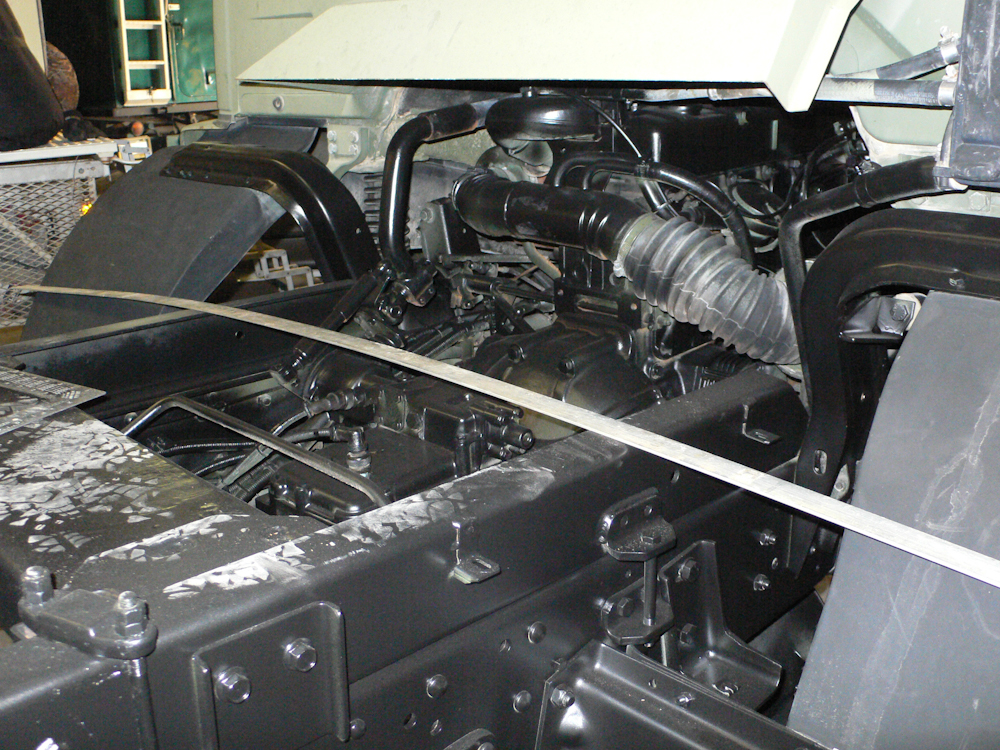

The

transmission shield was removed to allow additional room for mounting a

spare tire rack. Note the dusty foot prints on the frame from me

climbing on top to measure clearances to the rear of the cab cargo

bubble.

Above

is the tongue of the trailer after the propane bottles were

removed. The tongue will be cut off to allow fabrication of the

front mount for the cabin. The item in the box is the hydraulic

pump that raises the top of the HiLo.

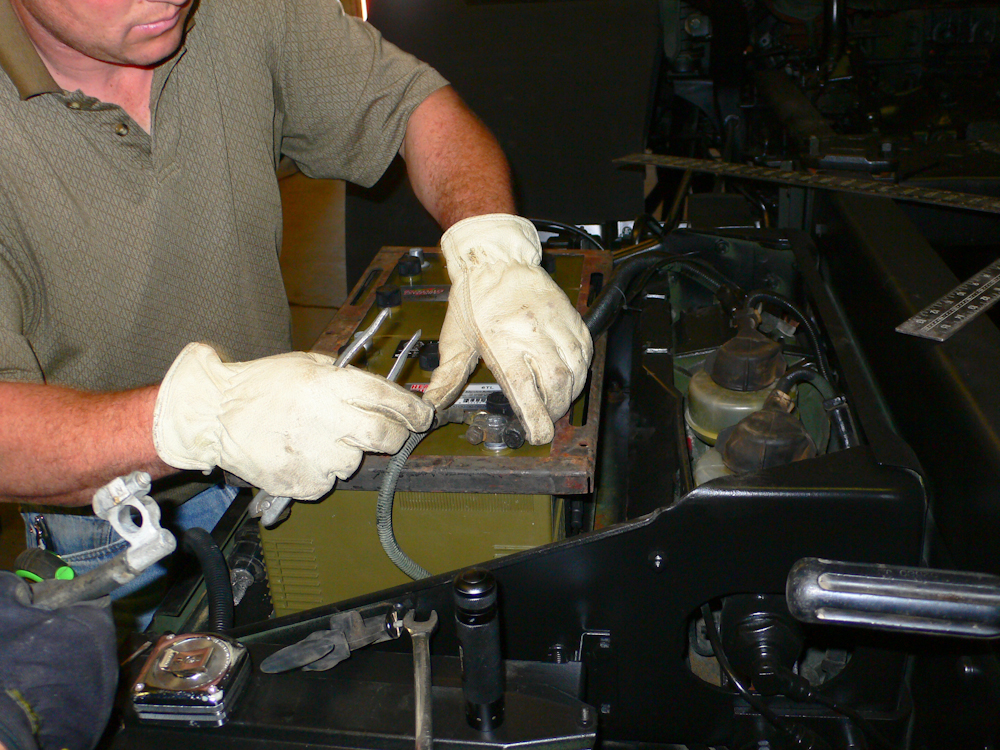

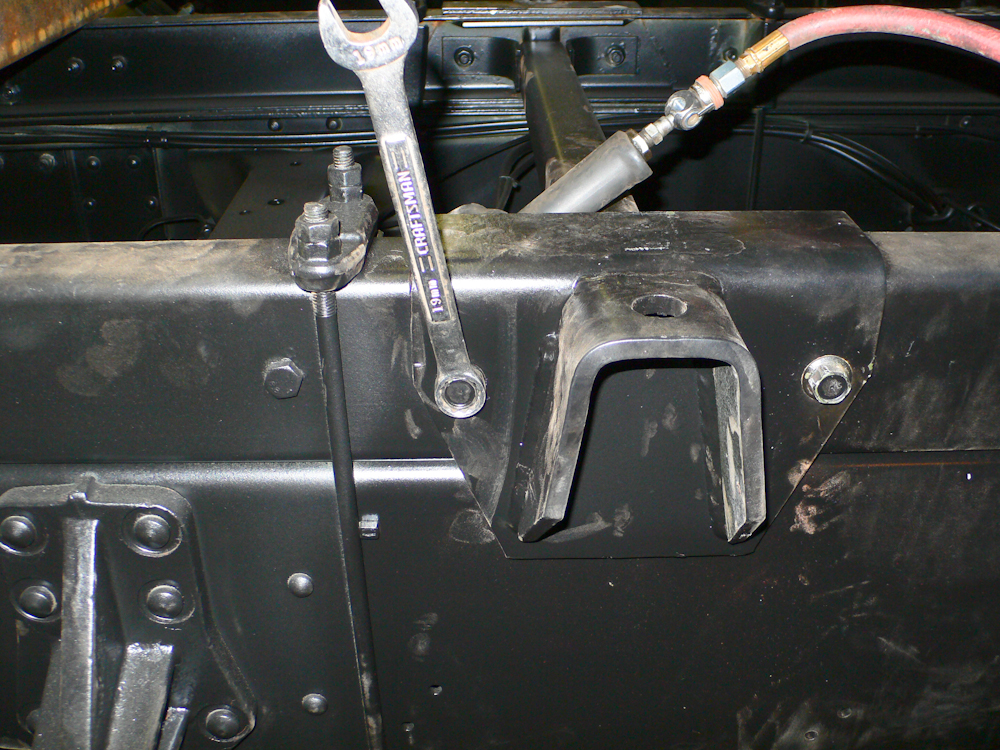

New

batteries were installed in the 1017, but the old battery restraint did

not fit well, so it was removed. It will be replaced with several

bars of steel and some "J" hooks to provide the battery restraints.

Kathleen

raises the cab on the 1017 in preparation for a fuel filter

change. And boy did it ever need a change!! Unlike my

1300L, this 1017 only has one filter and it was totally filled with

contamination.

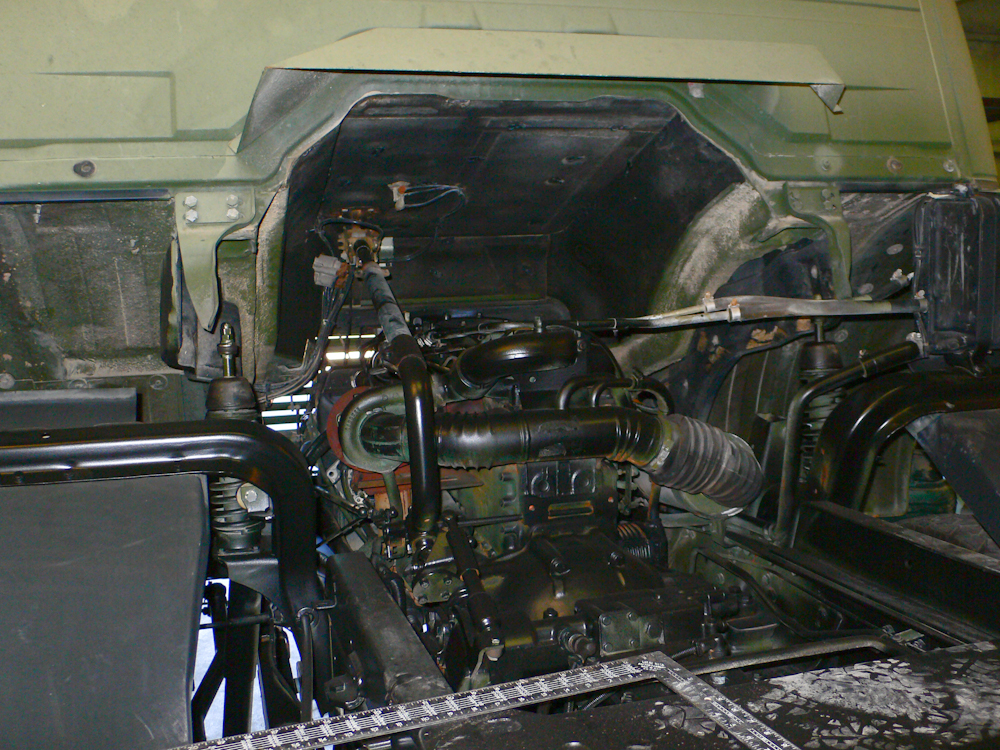

A

view of the engine compartment. The vertical bar to the left of

center in the photo above is the shift lever.

The

front of the tongue was cut off with a plasma torch. Above, the

plastic pan that supports the hydraulic pump and house battery can be

seen. This area will be transformed into the battery box for 4-6

volt golf cart batteries that weigh 62 pounds each. The new box

will have to be sufficiently beefy to support that much weight.

The tongue was cut off so that the front mount would be flush with the bubble on the HiLo.

The

trailer axle was removed.

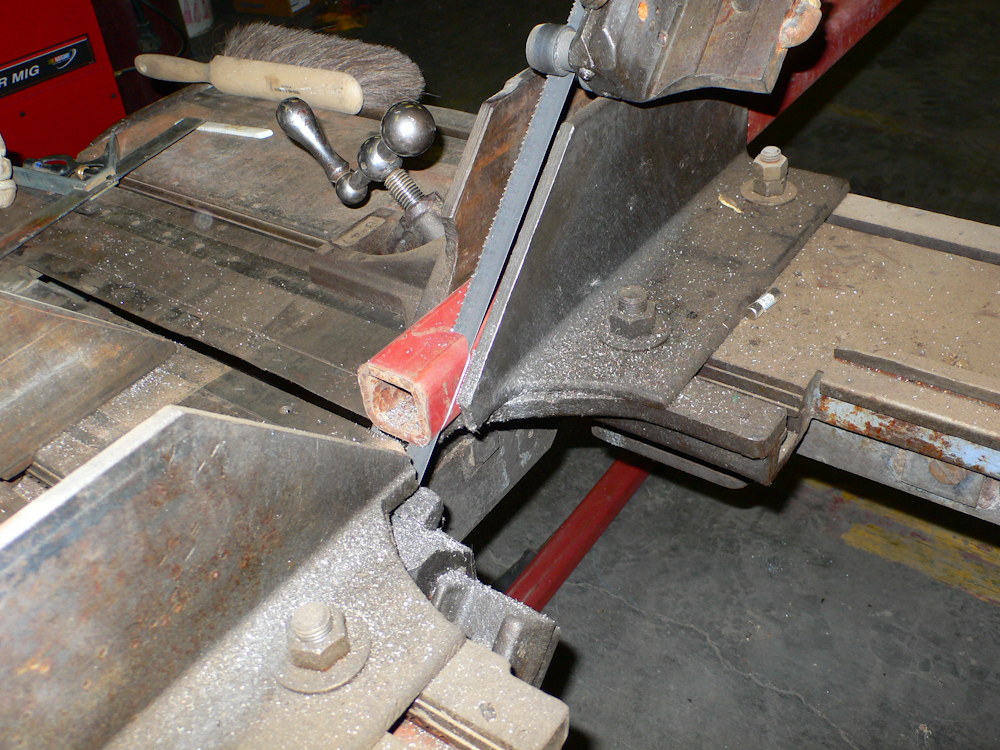

Rob's

industrial band saw was used to cut the 2x2 1/4" wall tubing that will

form the spare tire/generator rack.

One

of the tools of the trade: a plasma torch used to cut steel.

The

2x2 tubing was laid on the welding table prior to assembly into the

spare tire frame.

Assembly

of the spare tire frame is in progress. Above, the cross members

were inserted and positioned prior to tacking into place.

Cross

members were welded into place with the MIG welder.

The

band saw can make nice, clean cuts on thick material. Above, the

saw makes a square cut on the 2x2 tubing.

The

bed of the tire mount was laid on the frame for a sanity check.

While

we were working on the tire mount, one of Rob's other customers came by

with an issue on his U500. Some type of unusual air problem had

developed on the unit.

Rob

and the owner inspect the air system for issues.

While

they were addressing the air issues, I took a look around the

truck. The stock fuel tank and been replaced with this monster;

perhaps 100 gallons, maybe more.

Back

on the 1017, the foot cups and flex mounts were installed and tested

for fit prior to welding to the frame.

Several

beams were needed for the attachment of the HiLo to the 1017.

Above, one of the beams is laid-out prior to welding.

All

the fender skirts were removed from the trailer.

We

decided to re-use the stock bed mount for the HiLo. This mount is

massive and is designed to accomodate flexing in the frame during off

road driving..

The

finished beam was laid on the frame to provide visual confirmation of

the approach. Along the way, the rear fenders were removed to

provide clearance for the frame mounting hardware.

The

plasma torch creates nice fireworks when cutting ferrous metals.

Above, Rob cuts part of the stock mount to provide clearance for rivets

in the frame.

Good progress is

being made. So far, we are 3 days into the project and I am

pleased with the progress. We still have to complete the head

board for the tire mount, fabricate the tire lifting crane, complete

the mounting frame and lift the trailer onto the truck for a test

fitting. Additionally, there are a ton of external cosmetic

issues that need to be addressed as well as battery box fabrication and

all the internal modifications. A ton of work has been done, but

several tons remain.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text Copyright Bill Caid 2010, all rights

reserved.

For your enjoyment only, not for commercial use.