The photos below are what we saw.

Next to the visitor's center, there were a

number of antique

pieces of mining equipment. This is a steam engine used to run

a water pump.

The outside grounds were nicely landscaped and

included this multiple golden barrel cactus.

The growth pads of the

barrel cactus was filled with intricate structures.

This is a tooth from the

bucket of one of the production shovels. These wear out

and must be replaced every few weeks.

This is a steam-powered hoist.

This is an actual hoist head frame that was

moved to the visitor's center site.

Another steam-powered

water pump.

This is a small shovel bucket. The

current buckets are 6 times bigger.

This is a very early model

gas or kerosene-powered internal combustion

motor. The item on the top is an open radiator

tank. On the ground to the left is a drill bit.

This is a bucket used in

one of their smelter operations at another facility.

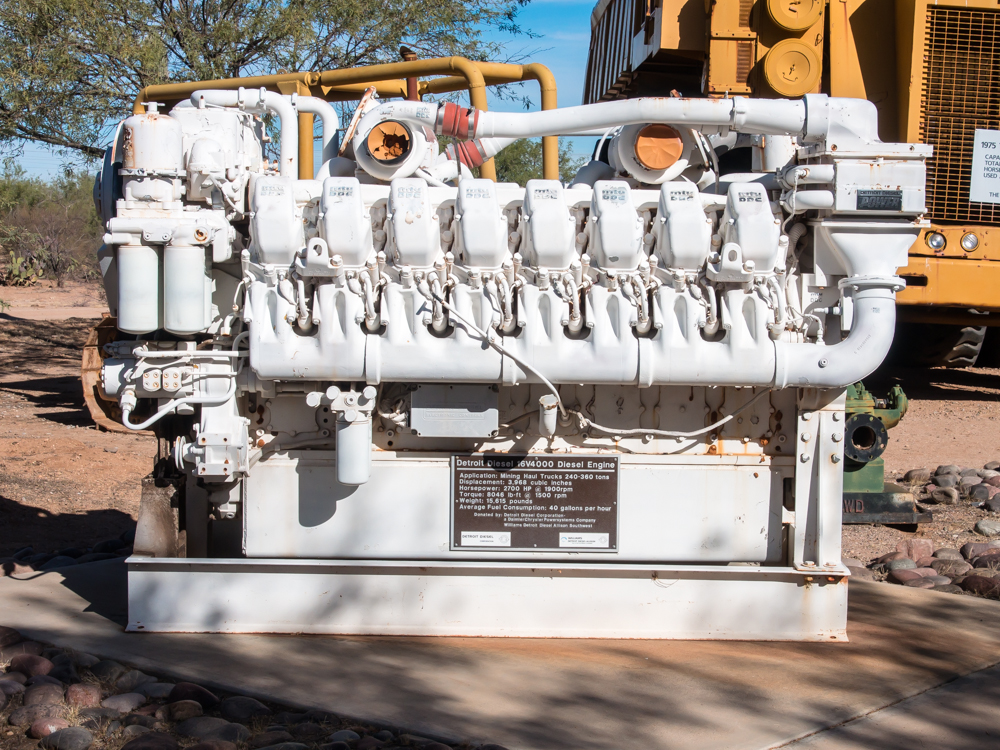

This is a 16 cylinder, 4000

cubic inch, 2700 hp diesel motor that puts out 8000 ft-lbs of torque and weighs 15,000 pounds.

Electric motors made rapid

inroads into the mining industry. They were much more efficient

and maintainable

than steam engines. The sled above is a water pump

driven by an

electric motor.

A much slusher bucket and

winch which is used in underground mines.

This is a 310 ton Terex haul truck that can

carry 160 tons of ore. Photos below show the current generation

of trucks.

I can only imagine the

effort required to change a tire.

I am surprised that the

truck was not sold as scrap. The tires are on the order of $80K each

when new.

We piled into the shuttle

bus for the tour and got a view of the tailings pond in the

distance (the white

area). The tailings are powdered rock and are pumped

with water to the pond where the water is reclaimed.

Soon we came upon one of

the current generation Komatsu trucks. This one was chugging up the grade from the

pit carrying overburden for dumping on the rim.

These trucks cost about $5M each and are diesel electric and are run

24/7 until a maintenance cycle is required.

The grade up to the dump

is steep and the trucks can only do about 6 mph when fully

loaded.

The first stop on the tour

was the pit overlook. In mining since the late 1950s,

they have moved 5-6 Panama Canal's worth of material. A

matrix of drill holes are being dug to allow emplacement of

explosive

slurry. These holes can be seen to the left of the drilling rig

in the center of the photo. Once the matrix

is completed, the

holes will be filled with explosive slurry and primers and

the whole shelf will be dislodged and then removed.

Depending on the copper content of the material, it will

either be loaded

into trucks and hauled to the dump site or to the

crusher for ore extraction. The steps on the left represent

the final

slope of the pit. All material not conforming

to that slope will be dispositioned to either the

dump or the crusher over time.

This bucket shovel is removing

overburden for transport to the dump site. The pond at the top of the

photo is at the

local water table. The shovels are electrically

driven with 4160 volt three-phase lines.

A

drilling rig is preparing blasting holes for slurry. Meanwhile, haul trucks are taking

ore to the crusher.

This shelf has already been

blasted into rubble. The rubble is being loaded into the

haul trucks.

Empty trucks

are always available to allow 100% duty cycle on the shovel.

The power cable for the shovel is visible

crossing the light-colored rock.

5-6 buckets are required

to fill a truck.

The haul trucks dwarf

conventional vehicles.

This pit is massive, but

nowhere near the biggest open pit copper operation. That

honor, I believe, goes to the mine at Silver City, NM. Santa Catalina Mountains

and their 9800'

peak are visible on the far horizon.

These trucks get going

over 30 mph when empty on the

downhill run.

The steep grades up to the

dump wall slow the trucks to 6 mph when fully loaded.

One of the settling ponds

where copper concentrate is separated from the processing

fluids.

Depending on the ore recovery schedule

and what is being removed from the pit, extra crushed ore

can be stored to

provide feed material when pockets of low concentration

ore is encountered in the pit. The partially

processed ore can later be added to the feedstock for

the ball mills.

When the partially processed

material is re-introduced to the feedstock, the material is passed through a

set of magnets to remove any steel grinding balls that may

have escaped into the ore. This is to prevent damage to the crushing machine.

The ball mills use 16 lb steel shot

to crush the ore into powder. As the mill turns, the

balls fall onto the ore and perform the crushing.

There are a set of these mills running 24/7.

The powdered ore is mixed

with water and a set of chemicals to neutralize acids from the

minerals and float

the copper to the top of these tanks. Scrapers push the concentrate into troughs where it is

washed out into settling ponds for recovery.

At the completion of the

tour, we returned to the Visitor's Center to see some of the displays. On

the exit from the facility, we spotted this awesome

christate sahauro near the road.

Normal sahauros have a circular

growth cap. This

christate has a growth line. Note the light colored

line at the crest of the cactus.

From the mine, we headed

south to Tubac to see the presidio. Most of the

exhibits were dimly lit, but still interesting. This

is a hand

made grinding wheel used for producing flour.

This is the way that the

indians did it: a metate and mano.

Another hand-made grinding wheel, this one

a bit more sophisticated.

To the east of Tubac, the Multi-mirror

telescope was visible on the peak of Mt. Hopkins.

An old wagon at the Tubac museum.

| Previous Adventure | ||

| Trip Home Page |

Photos and Text Copyright Bill Caid 2013,

all rights reserved.

For your enjoyment only, not for commercial use.